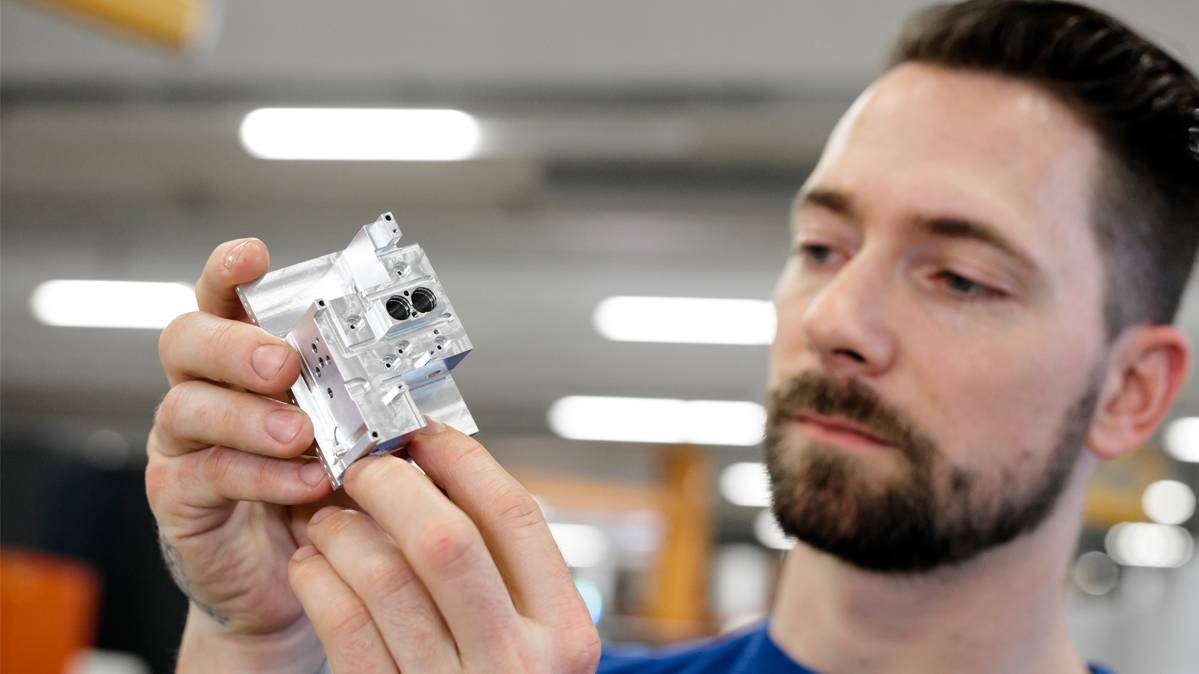

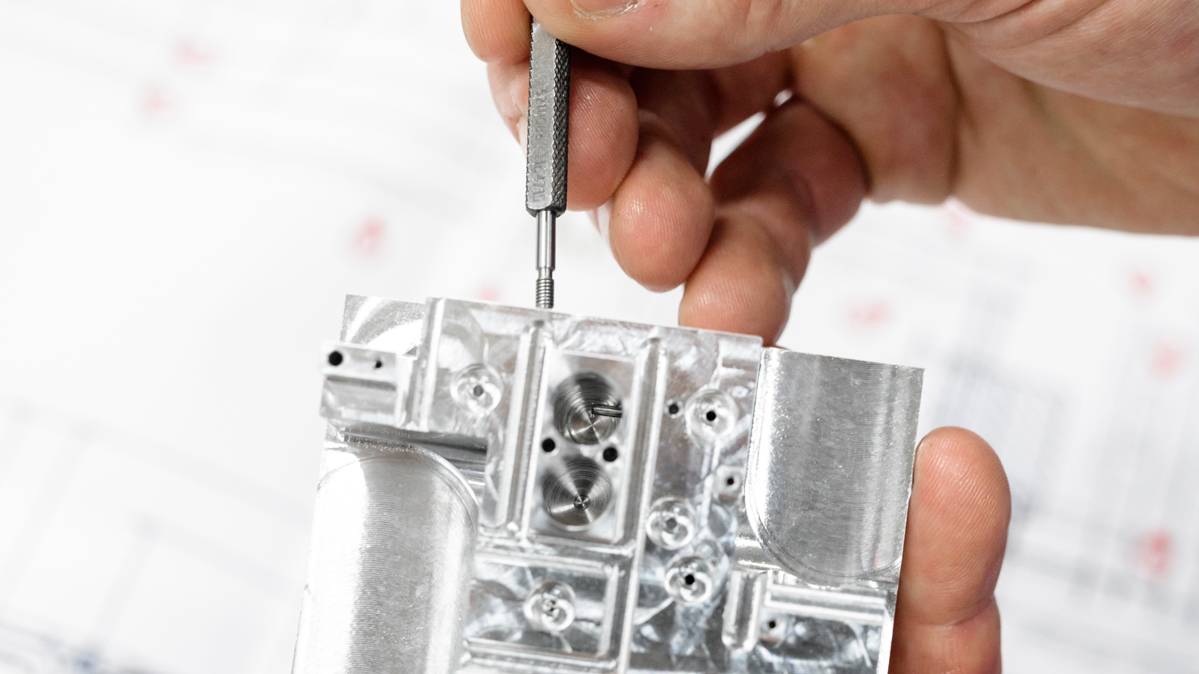

Milling. Precision milling. 5-axis milling

The tighter the tolerances, the higher our milling professionals ramp up their performance capabilities. Whether they employ simple 3-axis machining centers or 5-axis precision machines including palette handling and robots, our CNC mechanical specialists can process even the most complex workpieces with optimal throughput times.

Dimensions

- Milling parts up to 3600 mm in length

- 5-axis machining, up to 800 × 800 × 800 mm cubic

Machinery

- GF Mikron HPM 450 U (5-axis) 600 × 450 × 450 mm

- GF Mikron Mill P (5-axis) 800 × 800 × 550 mm

- Toyoda FH 450S Ø 630 × 750 mm

- Toyoda FH 45S Ø 630 × 750 mm

- Syntak MRU 32 (5-axis) 700 × 600 × 500 mm

- RemaControl Newton Big (5-axis) Ø 800 × 6000 mm

- RemaControl Newton Big Ø 800 × 2500 mm

- DMG DMU 50e (5-axis) Ø 500 × 350 mm

- DMG DMU 50 evo – 5-axis 500 × 420 × 380 mm

- DMG DMU 60 evo – 5-axis 650 × 500 × 500 mm

- DMG DMU 80P (5-axis) Ø 800 × 800 mm

- Haas Super VF-3 1016 × 508 × 635 mm

- Haas Super VF-3SS 1016 × 508 × 635 mm

- Haas VF-6SS – 1626 × 813 × 762 mm

- Haas Super VF-6Z 1626 × 813 × 762 mm

- KIA VX-500 1060 × 480 × 630 mm

Services

- Assembly

- Ultrasonic cleaning

- Superfinishing (belt grinding for piston rods/shafts)

- Roller burnishing

- Ball polishing

- Barrel finishing

- 3-D measurement technology

- Logistics

- Marking